proactive experienced passionate

reliable

Founded by masters in there own fields and driven by passion

for what they do.

With over a century of combined knowledge between the founders and the leadership team, the Grizzly Group has a solution to your requirement when it comes to machinery maintenance and personnel supply. We will endevour to be the best at what we do in the safety and most cost effective way.

workout plan

all-year pass

one-on-one

GRIZZLY.

GRIZZLY.

Heavy-mech

At Grizzly Maintenance Group, we are not just a maintenance service provider, we are a large heartbeat of mechanical reliability within the mining industry. With a dedication that transcends mere duty, we live and breathe mechanical maintenance, ensuring the uninterrupted operation of machinery operations in open-cut, underground, and heavy haulage environments.

Unrivaled Expertise:

Our team comprises of seasoned professionals with deep-rooted expertise in mechanical maintenance specific to the mining sector. From heavy machinery to intricate systems, we possess the knowledge and skills necessary to tackle the most demanding challenges inherent in the industrial sectors.

Comprehensive Solutions:

We understand that the mining industry operates around the clock, and downtime is not an option. That's why we offer comprehensive maintenance solutions and personnel tailored to the unique requirements of each operation. Whether it's preventive maintenance, corrective repairs, or predictive maintenance strategies, we have the tools and techniques to keep your machinery running at peak efficiency with minimum downtime.

Labour hire of trades, T.A’s and labourers.

GMG have you covered when it comes to getting feet on the ground, bums in seats and supervisors / managers where required.

GRIZZLY.

GRIZZLY.

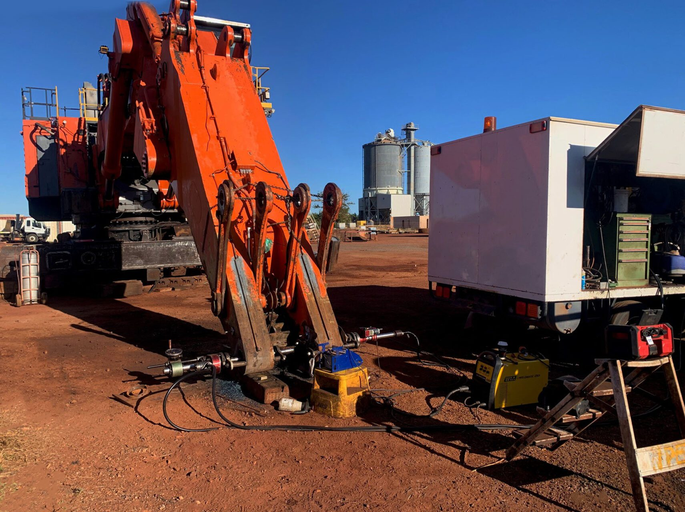

hydraulics

"Grizzly Hydraulics/ component rebuild services was born out of necessity during covid as the supply chain into Australia crumbled and the demand for

on site hydraulic repairs and major component refurbishment was in high demand.

Grizzly group has mobile personnel as well as in house first class machinists, fitters and hydraulic techs that can take care of all hydraulic hose / fitting requirements as well as rotating assembly needs.

Grizzly Hydraulics can supply , design and install custom grease / lubrication systems for you mobile or fixed plant machine. No matter the size, we can install a system that will best suit your application.

GMG has undertaken works for major manufacturers and companies include a vast array of tier 1 mining contractors as well as large machinery manufacturers such as Liebherr, Hitachi, CAT and Komatsu.

GRIZZLY.

GRIZZLY.

engineering

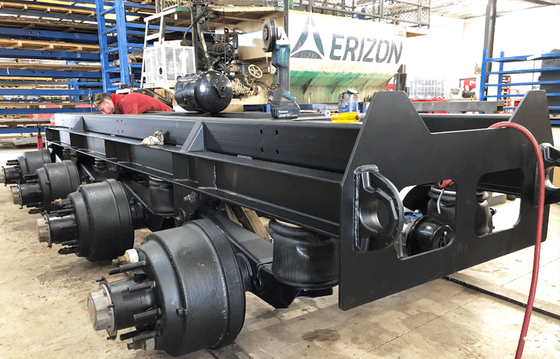

"Grizzly Engineering in conjunction with our sister group offer state of the art facilities when it comes to engineering and fabrication.

From autonomous welding for mass production to cnc cutting upto 300mm thick plate, nothing is impossible.

With all facilities in house including design, cut, fold, weld, blast, paint and deliver, the turn around times are shorter and quality of works are higher with implemented QMS.

Onsite heavy fabrication / line boring and bushing

With high demand for onsite line boring, rebushing, tray and bucket refurbishment, GMG have taken the opportunity to design and build an on site boiler maker setup containing a diesel driven electro and compressor unit accompanied with multiple welding units as well as a milling heads that are capable of cutting upto 400mm diameter.

Wear plates and packages

GMG can design, cut and install wear packages to suit your needs.

from BIZ plate, ceramic blocks, bucket lips, profile cut shrouds, rolled plate skins, let us do the hard work for you and build something better than OEM that will last longer and increase uptime.

Plate cutting and folding

with multiple automated CNC units in house, GMG can program, cut, strap and deliver plate from .6 to 300mm to your door

Custom engineering

This is where Grizzly Engineering exceeds its customer expectations.

With the capacity to reverse engineer, improve, modify and create a hand sketched idea.

GMG have the talent and engineers to design and create a product that could be the tipping point to revolutionize your business.

Having extensive knowledge in the crushing, processing and mining sector, we have been privelaged enough to work with companies to design and build shaker decks, trommels, conveyers, wear packages, jaws, buckets and many more one off components.